Try our neural network for free

The Trial Service allows users to test AgnosPCB’s Automated Optical Inspection (AOI) service for free, using your own camera to check the integrity of their assembled Printed Circuit Boards (PCBs)

AgnosPCB is fast and reliable. Why not check it out by yourself?

Benefits of our AOI System

Price

Our AOI systems cost a fraction of what a conventional AOI costs and we offer much more than what you can find on the market.

Space & mobility

Our automated optical inspection machines take up much less space than our competitors' machines, making them easy to move and store.

Solutions

We offer different ways to use our neural network software; machine online, machine offline and API.

Adaptable

Our software is focused on checking pcb boards but can be adapted to check other objects.

Discover how our AOI can help you find issues in your PCBS

Detect component faults in seconds with neural network AOI. No programming required, just use your camera.

Can I use any camera?

Yes, you can, but the AgnosPCB neural network AOI software will need the best possible photo of the PCB in order to provide optimal results.

If you want to test the service, feel free to use a smartphone camera, but keep in mind that you will not get the most of the Agnospcb AOI software.

IMPORTANT: Quality of the inspection results

Requirements

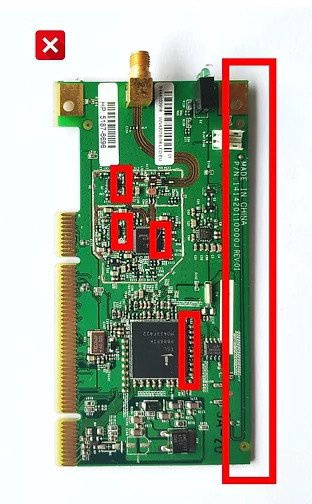

A minimum of 12Mp photography is mandatory. The quality of the photography is highly depended on the camera sensor / optics.

Low resolution, blurred or non-detailed images of the circuits/panels you want to inspect, will lead to poor fault detection results. Try to take the best possible photos following the tips listed below.

Trial account does not offer all the features

Small faults as short-circuits or defects related with 0402 size elements may not be detected if the photos lack of enough resolution.

For the best possible detection results, we have designed an inspection platform based on the powerful APS-C 24 Megapixels sensor. Contact us for more info.

This Webapp of the trial account is fully functional, but does not offer all the features currently available.

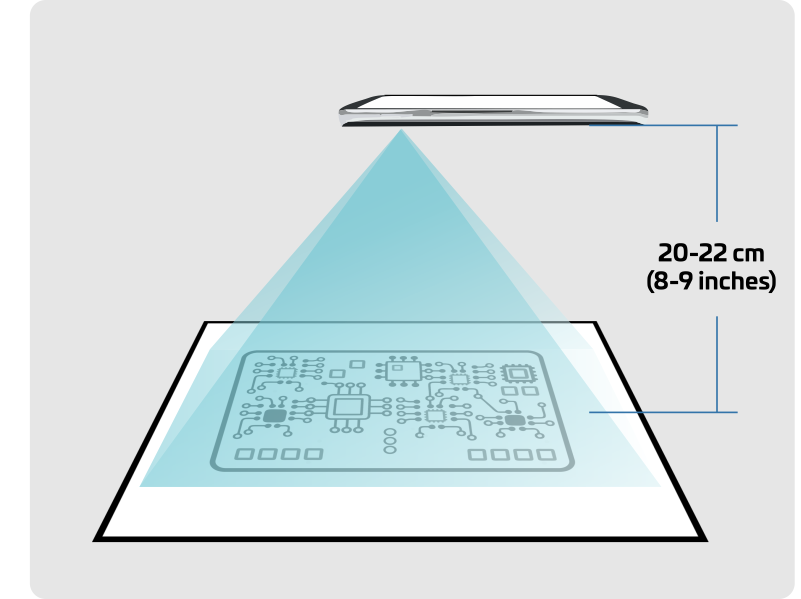

Using a smartphone to check the PCBAs integrity

1) Get your smartphone

You will need good camera smartphone. The better the camera, the better the visual inspection detection. Almost any mid-range, not too old, smartphone will work. Place your board on a light color surface. The photo has to be taken from a distance of approximately 20-22 cms (8-9 inches).

We strongly recommend using a tripod so the smartphone will stay steady during the process.

2) The reference board

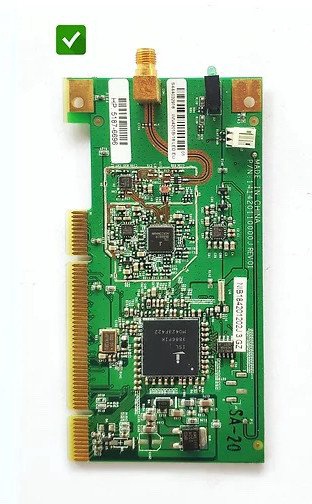

First, you will need to set a reference board. An example of what the neural network will use to compare all the PCBAs with. A “golden sample” This reference board will be a pre-checked and working condition PCB.

TIPS:

- Do not use digital zoom

- Center the board/panel in the photo

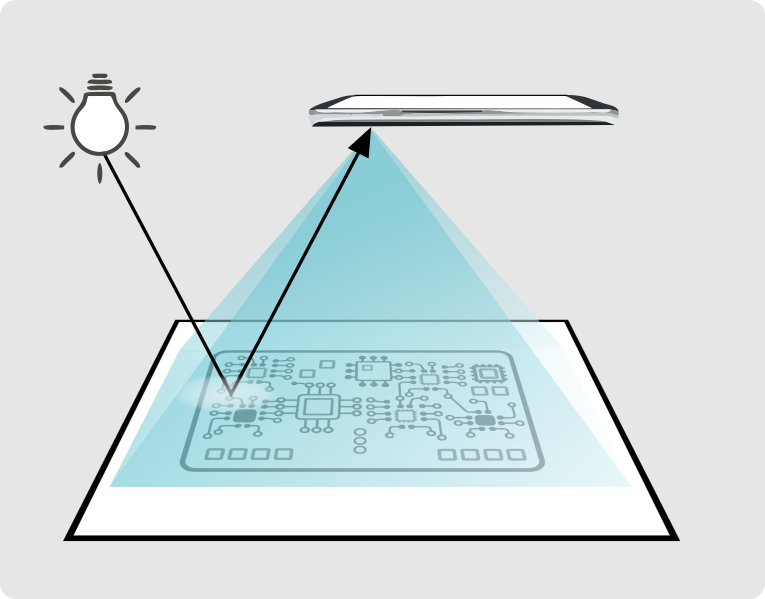

- Avoid to all cost light reflections on the board. Uniform lighting conditions will bring the best inspection results. Keep in mind that the neural network will not see what a technician can not see on the photo.

Avoid casting shadows

That will reduce the visual inspection capability to detect faults

Keep away direct light sources from the PCB.

They will create reflections on its surface

A good ambient light

and a detailed photo will drastically improve the detection capabilities

3) Take photos of the boards to inspect

Now, once the reference board has been set. Take photos of the boards to inspect.

A perfect alignment or placing the board always in the same position is not mandatory. The neural network will take care of correcting perspective and orientation but try not to place the boards too far from reference board original location.

TIPS:

- Do no cast shadows with your hand or any other object.

- Blurry photos will provide poor results.

Using the WebAPP to inspect the boards

The WebApp allows you, in a fast way, to inspect the board using a simple user interface. Just drag and drop the photos taken to your PCBAs to check their integrity. For a better results analysis, we recommend using the Agnospcb inspection tool software.

You will need a USER ID in order to get access to the inspection tool. Contact us if you are interested. Once you get one, you are set to go.

Trial account user guide

Essential reference guide for getting started with your trial account via the WebApp or the Inspection tool software for Windows. Go to Trial account user guide.

You can also choose an online plug & play solution or use our API.

Built for companies that want the best service at the best price. Simply connect directly to our neural network online.

Built for companies that demand maximum privacy. Everything runs locally, with no online connection to our neural network.

We are always ready to help you and answer your questions

If you need extra information about our products and services, get a trial account or want to rent an AgnosPCB AOI unit, please fill the following form.

Our support team will contact you as soon as possible.

USA

EUROPE

Hardware R&D and Test Office, 871 Harold Pl., Ste 112

San Diego, CA, 91914, United States info@agnospcb.com

PCTT Tenerife, C/Rectora María Luisa Salguero

Las Mantecas, 38320, Tenerife, España info@agnospcb.com

EUROPE - GERMANY

Munich

Michael Matauscheck michael@agnospcb.com