What are not considered faults BY the Agnospcb inspection software?

Agnospcb AOI software is not a pixel comparator. It knows what an electronic component is. Consequently, it will discard all existing elements that are of “no importance” to the functioning of the circuit or panel, and focus on looking for real defects.

These are:

- Displacements / tombstones

- Non-presence

- Excessive rotation

- Short circuits

- Collisions between components

- Polarity errors in components

- Contamination

- Deformations in geometry

- Bent pins

- Damage components

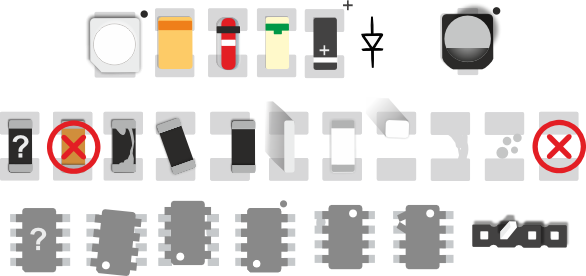

In the same way, there are obvious differences between circuits that are not defects:

- Silkscreen variations

- Annotations

- Stickers

- Coding, barcodes

- Light reflections

- Others

A conventional visual inspection system requires constant adjustment of its inspection parameters in order to leave out the above unimportant variations from the analysis. AgnosPCB does not require this.

An electronic component can perform its function perfectly even if it is slightly displaced or rotated (this is the case of capacitors, resistors…).

The AgnosPCB AOI software knows that, but moreover, it knows that a rotation of a component, depending on its location, can represent a serious problem: it can collide, or place itself on a pad after the reflow oven stage.

All these types of errors are detected and highlighted by the software.

The system is of the conservative type: in case of doubt, it will flag an error for further inspection.

Left:

Video showing how Agnospcb inspection software works. PCBA photos donated by a client. Photos taken using a smartphone.

Geometry variations are not taken into consideration, just real faults.

This way of processing helps enormously to save time and consequently money when checking the integrity of an electronic circuit.

No matter how many elements are present in the circuit or their position: the processing time to check for faults only takes few seconds.

Want to try it for yourself? You can use a conventional camera, even a smartphone camera*, to check it in situ. Contact us, and we will create a trial account and give you free access to our inspection software.

*NOTE: the quality of the inspection is strongly dependent on the quality of the photograph. Blurred or poorly detailed photographs have to be avoided. AgnosPCB has created an inspection platform to facilitate the process of analyzing the circuits/panels.