AI Technology

AgnosPCB leverages AI Technology in its Automated Optical Inspection (AOI) service to enhance the inspection process of assembled Printed Circuit Boards (PCBs). The AI, in the form of a neural network, is used to compare inspected PCBs with a “good condition PCBA” (Golden Sample), swiftly identifying and highlighting any faults. This technology is capable of detecting a wide range of faults, including missing components, misalignment, short-circuits, contamination, and polarity issues.

The AI adapts to the specific inspection requirements of any panel or circuit and can be used at any stage of the manufacturing process. This use of AI Technology significantly improves the speed, accuracy, and efficiency of PCB inspection, ensuring high-quality results.

Our neural network is a key component of the AgnosPCB Automated Optical Inspection (AOI) service

What is a fault and what is not?

Security and privacy statement

COMPONENT PLACEMENT INSPECTION AT ANY STAGE

AgnosPCB does not just contrast the integrity of your already assembled PCB. It can find any SMT placement fault on the solder paste layer after the pick-and-place process.

The same AOI system can be used in both stages.

This AOI system knows in which manufacturing process stage the PCBA is, adapt itself accordingly, and look for possible faults.

You do not need to do anything, everything is done automatically.

CAN I EMBED AGNOSPCB AOI SERVICE INTO MY EXISTING MANUFACTURING LINE?

Yes, you can. There is an AgnosPCB API you can use to upload your own PCBA images to our cloud server or your AgnosPCB local processing unit and get the results of the inspection within seconds. Contact us for more information.

What can this visual inspection do?

The neural network will use a “good condition PCBA” (GOLDEN SAMPLE) to compare any other circuits/panels. Then, just take photos of the PCBAs you want to inspect. The AgnosPCB software will highlight every fault found on them (if any). The process takes seconds. After looking for faults, this tool will mark on the photo of the circuit/ panel anything that will require to be doubled checked by a technician.

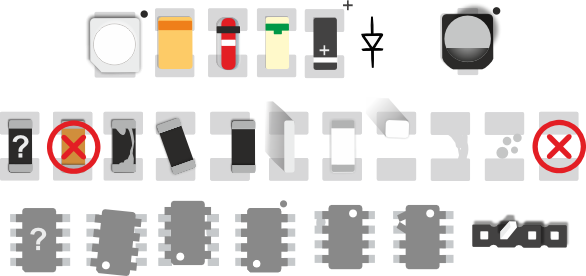

Type of faults detected:

- Missing components

- Misplaced or Rotated

- Misalignment

- “Tombstones“

- Short-circuits

- Contamination

- Polarity

- Bent pins

AgnosPCB AOI system Advantages:

- No need to pre-program the AOI system

- Can be used to check the PCBA after the Pick and Place and reflow oven processes

- Check the integrity of any panel/circuit even without the original Gerber/design files

- Fast and reliable

- Extremely cost-effective